Ergonomics and quality

The quality of tank cleaning is determined by two factors: a well-functioning installation and a well-trained cleaner with the right tools.

Automatic washing programs

Fixed washing programs form the basis for good cleaning. This way the tank cleaner can focus on other activities while the program does its work.

Training

Gröninger pays a lot of attention to instructing cleaners during the delivery of an installation. We have an extensive network of experienced operators who can also be deployed on an interim basis.

Tools

We offer various tools in the workplace, such as high-pressure guns, foam guns and atomization systems. In addition, the vacuum extractor is a useful tool for quickly inspecting tanks, while compressed air quickly removes vapors.

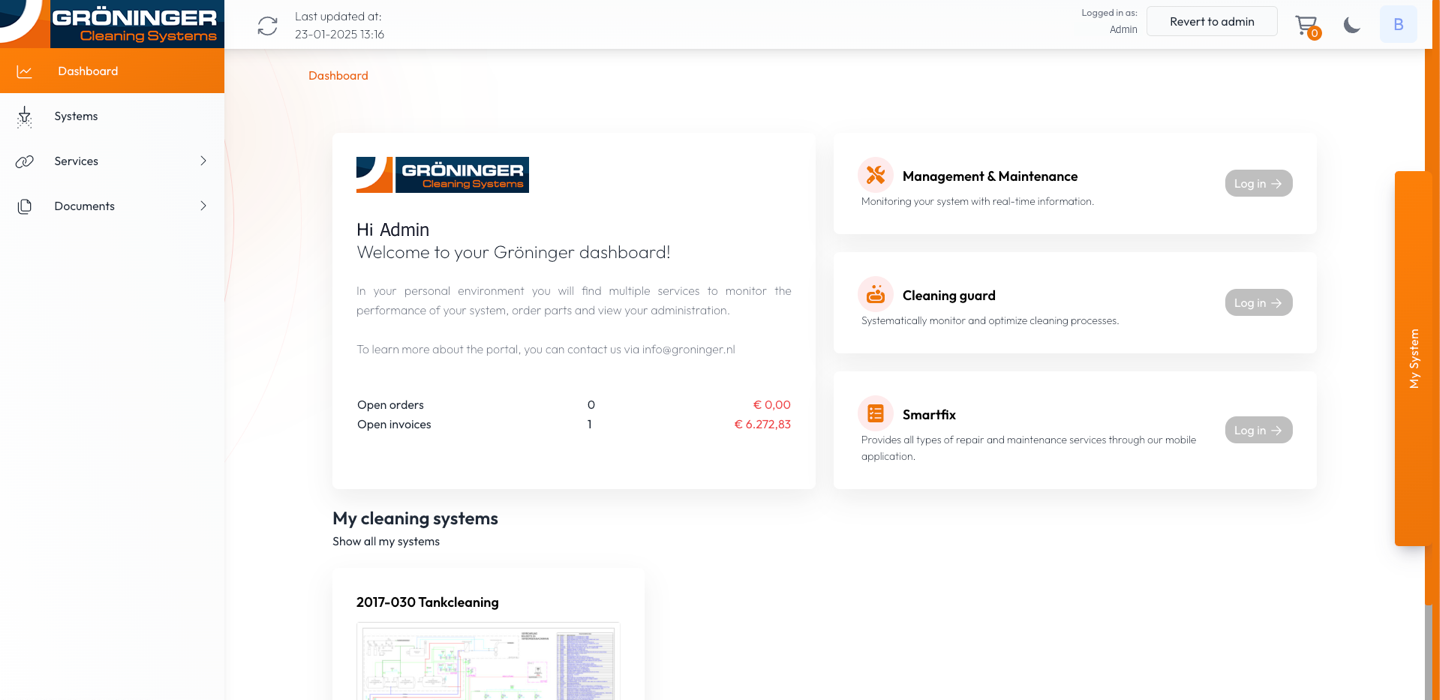

Service & Support Beyond Cleaning

For service & support there is only one point of reference: the customer and his cleaning activities. The Gröninger service and support modules are based on detailed analyzes of customer requirements. The focus is on efficient and effective processes.

In addition to the fact that Gröninger develops and supplies customized installations, we also offer customized service, maintenance and support, under the name “Support Beyond Cleaning”.

Safety comes first

Cleaning tanks is not without risks. The tanks sometimes contain aggressive or explosive chemicals. But the use of hot water under high pressure and working at heights can also pose major risks. Gröninger tailors the technology to these risks and makes no concessions in the field of safety.

Fall protection

With fall protection you can choose between individual and collective systems. Individual systems ensure that the cleaner secures itself with a hook on a fall arrester. In the event of a fall, the fall is broken by the fall block, ensuring optimal freedom of movement for the operator.

Grounding

There may be a risk of explosion when cleaning certain products. A solid grounding system safely dissipates static electricity without sparking, which significantly reduces the hazard.

Sustainability and energy supply

Energy plays a significant role in the cost of tank cleaning. That is why our sustainable tank cleaning systems pay for themselves. We provide energy-saving solutions to help companies operate greener and reduce costs. Our attention is focused on:

Sustainable steam and central heating systems

You can choose between a steam boiler or central heating boiler to heat the washing water. The steam boiler or steam generator not only heats the water, it also takes care of pre-steaming, sterilizing and kosher cleaning of the tanks.

Energy saving

We apply various techniques to reduce energy consumption, such as frequency controllers, flue gas condensers and waste water cooling.

Alternative energy sources

In addition to the classic steam and central heating boiler, we use other heat sources such as pellet stoves, cogeneration, geothermal heat pumps and solar collectors.

Want to know more about our sustainable techniques? Then click here.