In 2021 Gröninger Cleaning Systems has built a new tank cleaning facility for Imperial in Terneuzen. As with most projects, this was preceded by the necessary preparations. The system is now running at full speed. We meet with Rob Libbers, who on behalf of Imperial has taken care of this project from A to Z on behalf of Imperial.

“As manager of Imperial tank cleaning operations in the Netherlands, I have been closely involved in this project for some time. The former facility - also built by Gröninger - had been in use for 30 years. So it was really time for something new. We deliberately moved to a completely new location. On the basis of our many years of experience, we also knew exactly what was needed and what the market was asking for. That process took some time due to many factors and circumstances, but you can only do it right once. And I really have that feeling now.”

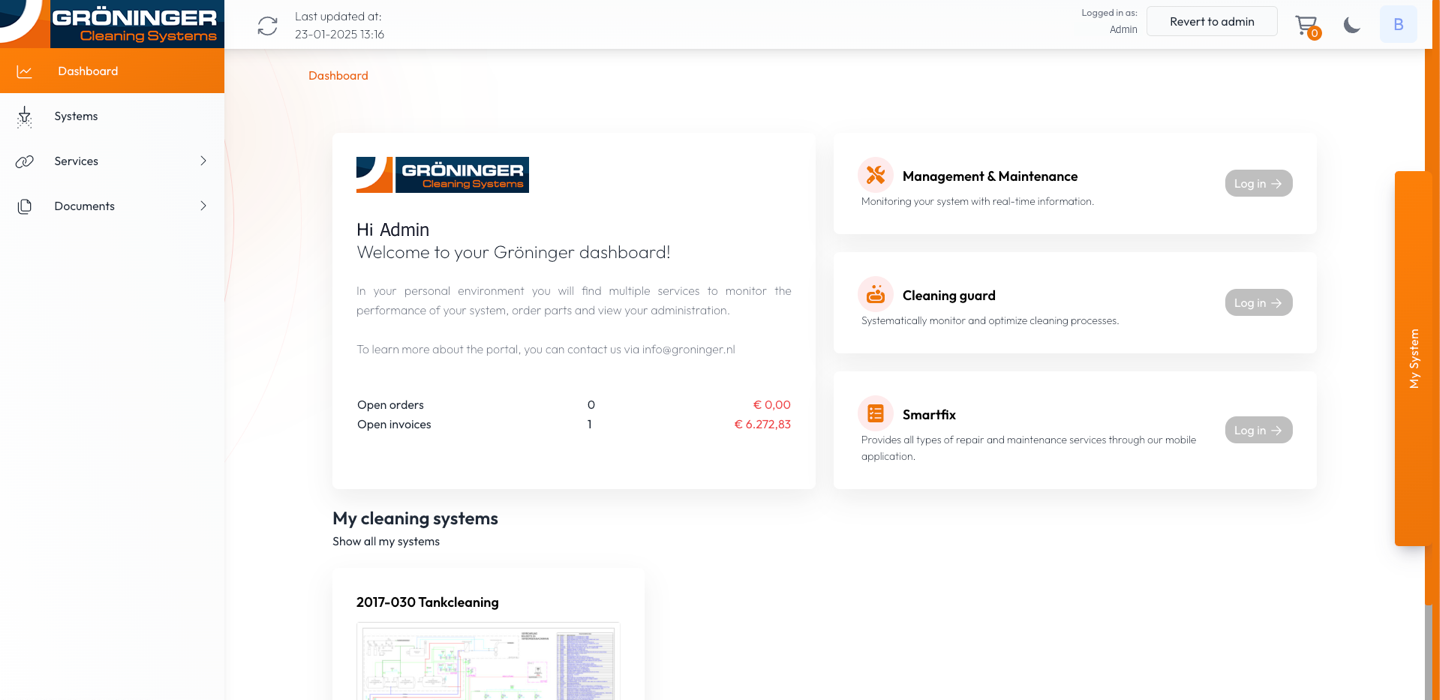

The Gröninger team can confirm that this is correct. As early as 2013, Gröninger and Rob Libbers made an exploratory reference visit to a newly completed tank cleaning facility. Several visits followed in the years after. As the project gained momentum, numerous preparatory discussions were held with Imperial as well as with the building contractor. Together with Rob Libbers, Joost Kasbergen and a other technical colleagues everything was prepared down to the final details. Then the first pile could be driven into the ground with peace of mind.

In addition to proper planning and the technical setup of the system, the location and logistics for a tank cleaning are extremely important. Rob continues: “We are now located at a very good spot on the map for our customers from Antwerp and Ghent and surroundings. A very large chemical producer is literally around the corner in Terneuzen, less than 15 minutes away. Moreover, we are closer than before to a very important customer, a transport company for which we do a lot of work. And last but not least, for Imperial's own tank transport we are very centrally located as well. This way everyone who needs to clean tank lorries and containers benefits. So the new knife cuts both ways.”

We continue the tour and enter the cleaning facility. Everything sparkles and shines. It looks state of the art and well organized. But what kind of technology was applied and why was this selected? "Our aim above all is to increase quality, in order to meet the current requirements of shippers," says Rob. "We have opted for a completely different set-up for the new cleaning. Previously we cleaned at 60 bar, now the standard is 100 bar and for some products we even have 200 bar available. That makes a difference. Our customers do transport a wide range of products. Some products are what we call 'heavy duty' chemicals, including class 3 products; we can now flush these products much faster and more effectively at 200 bar. An further advantage is that much less water and less time is required. In the course of time you recover the investment and our customers will benefit right from the start from higher quality. With this 200 bar we are truly unique in the wider area of Terneuzen. At other tank cleaning sites in the Netherlands you now more often see 200 bar, so it is really a trend.”

But innovation doesn't stop here. We continue the walk to a room, actually a whole cleaning bay, with a special piece of equipment: “This is a so-called latex circulation unit, the only one for miles around. Latex is a common cargo. We deliberately chose this unit so that our employees do not need to enter a tank. That has to do with safety and related aspects. That is a top priority at Imperial.” The system circulates hot water with a cleaning agent at a relatively low pressure and with high volume through the tank, thereby rinsing the tank thoroughly. Finally the key question arises, what are you doing differently and better than before? “We do everything we can to distinguish ourselves with our services in this region. There includes everything that I have already mentioned and what you have seen too so far. But I almost forget something very important and that is the 24/7 service to heat tankers and tank containers with products using steam. Some products must be kept at a constant temperature, others must have a certain temperature in order to be processed directly in a factory. So we take care of that too.”

In the current time, you can't ignore sustainability aspects - and rightly so. Gröninger contributed key knowledge and skills in this field. For example, heat is recovered via the flue gases from the boiler to preheat water. By applying more pressure, the lead times are a lot shorter, which also saves energy. And by using washing programs the procedures provides exactly what it takes to get the tank thoroughly clean, saving water, gas or oil, chemicals or steam. All in all, significantly more tankers and containers can be cleaned per day with less input than before.

While the next tank lorries are already entering the tank cleaning, this fascinating guided tour with Rob Libbers comes to an end. He and Imperial have every reason to be proud. On behalf of Gröninger we wish Imperial a lot of success. Imperial is clearly fully equipped and ready for the present and the future.