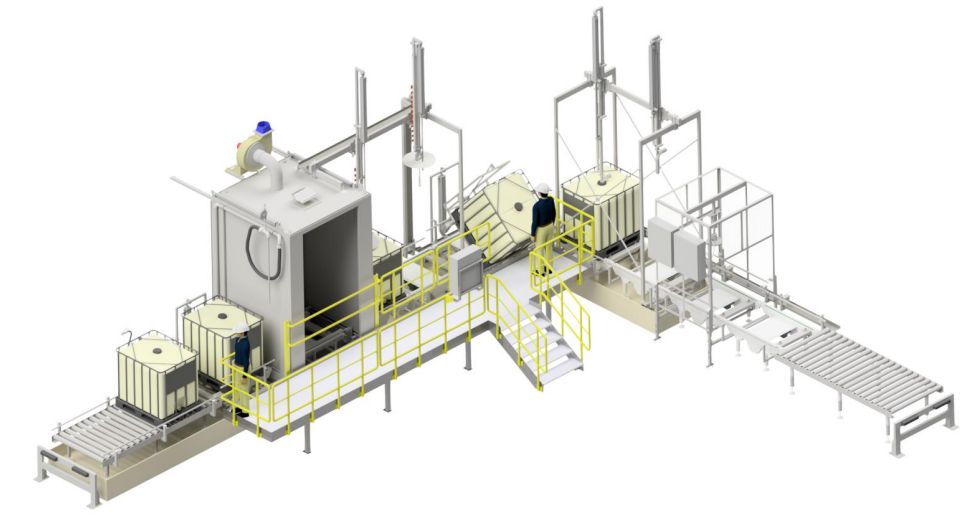

Gröninger IBC cleaners are available in all kinds of variants, from manually operated to fully automatic. In addition to IBCs, they are suitable for stainless steel tanks or product containers used in industry and logistics. There are different starting points in terms of cleaning principles (recirculation systems or lost cleaning) and the settings involved (temperature, pressure, cleaning agents and cleaning time). The optimal technical configuration is determined in consultation with Gröninger. The installations can be constructed separately or as a cleaning cabin. The most important functions are:

IBC cleaning: internal and external

The internal cleaning of a container is done with a rotating washing head and can be carried out at different operating pressures. This is inserted manually or automatically into the IBC or stainless steel container. The external cleaning of IBCs or stainless steel containers can be carried out both manually and automatically.

Suctioning and drying IBCs

After internal cleaning, some residual water always remains in the IBC. To quickly remove this water, it is sucked from an IBC with a pump or vacuum cleaner. This can be done automatically or manually. After this, the IBC is dried by forcefully blowing hot air into the IBC through a blow pipe. Gröninger supplies Drypack drying installations for this purpose. These extraction and drying systems give very good results: the IBCs are dry within 6 minutes!

Leak testing of IBCs

IBCs must be inspected and tested periodically. One of the inspections is a density measurement. This measurement can be performed with a Gröninger IBC leak test installation. An IBC is placed at overpressure for a certain period of time, after which the installation measures the pressure loss. If the IBC loses pressure too quickly within the specified conditions, it can be concluded that it is leaking and must be rejected. The leak test installations offer various options depending on the customer’s needs.

Disinfect, sterilize and steam

Before, during or after cleaning, there are technical options to perform these functions, depending on the area of application.

The Gröninger IBC cleaning installations can therefore be technically equipped in all kinds of ways. At least as important is the attention that Gröninger, based on extensive experience, pays to internal logistics.

Consider: removal/supply and storage of clean/dirty packaging; method of internal transport; physical location of cleaning installation/technical room; flushing water drainage (gutters, drip trays, etc.); relief; ventilation (vapour formation); half heating and residual product disposal.